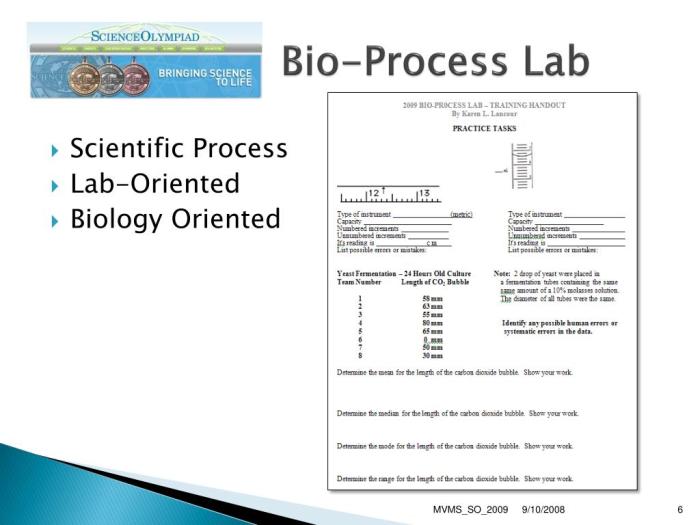

The Bio Process Lab Science Olympiad emerges as a prestigious platform for young minds to delve into the captivating world of biotechnology. This academic competition ignites passion for scientific inquiry, fosters critical thinking, and cultivates a deep understanding of the intricate processes that underpin life sciences.

Through hands-on experimentation and rigorous knowledge acquisition, participants embark on a journey that unveils the fundamental principles of bioprocess engineering, cell culture techniques, bioreactor design, and downstream processing. The olympiad provides a fertile ground for nurturing future leaders in biotechnology, empowering them with the skills and knowledge to address global challenges and drive scientific advancements.

Bio Process Lab Safety

Maintaining a safe working environment in a bio process lab is paramount to prevent accidents, protect the health of personnel, and ensure the integrity of research findings. Stringent safety protocols are essential to minimize potential hazards associated with biological materials, chemicals, and equipment.

Common safety hazards in bio process labs include:

- Exposure to hazardous biological agents (e.g., bacteria, viruses, fungi)

- Exposure to toxic chemicals (e.g., solvents, acids, bases)

- Fire and explosion risks

- Electrical hazards

- Slips, trips, and falls

Mitigating these hazards requires adherence to established safety protocols, including:

- Proper handling and disposal of biological materials

- Use of appropriate personal protective equipment (PPE)

- Regular maintenance and inspection of equipment

- Emergency preparedness and response plans

- Regular safety training for personnel

Personal Protective Equipment (PPE)

PPE plays a crucial role in protecting lab personnel from potential hazards. Proper use of PPE includes:

- Wearing appropriate lab coats, gloves, and safety glasses

- Using respirators when working with hazardous biological agents or chemicals

- Wearing earplugs or ear muffs when working with loud equipment

- Wearing appropriate footwear with non-slip soles

- Ensuring PPE is properly fitted and maintained

By adhering to these safety protocols and using PPE correctly, personnel can significantly reduce the risks associated with bio process lab work and maintain a safe and productive environment.

Equipment and Materials

A bio process lab requires specialized equipment and materials to facilitate various procedures and experiments. Understanding their functions, calibration, and maintenance is crucial for accurate and efficient laboratory operations.

Essential Equipment, Bio process lab science olympiad

- Autoclave:Sterilizes equipment and materials using high-pressure steam.

- Centrifuge:Separates particles based on density and size by spinning at high speeds.

- Incubator:Maintains a controlled environment for cell cultures or microbial growth.

- Microscope:Magnifies samples for detailed observation and analysis.

- Pipettes:Measure and dispense precise volumes of liquids.

- Spectrophotometer:Measures the absorbance or transmittance of light through a sample.

Calibration and Maintenance

Regular calibration and maintenance ensure the accuracy and reliability of equipment. Calibration involves adjusting the equipment to known standards, while maintenance includes cleaning, lubrication, and replacement of parts as needed.

Materials

- Culture media:Provides nutrients for microbial growth.

- Chemicals:Used for various reactions and assays.

- Consumables:Includes items such as gloves, pipette tips, and petri dishes.

Cell Culture Techniques

Cell culture involves growing cells in a controlled environment outside their natural context. This technique enables the study of cellular processes, drug screening, and the production of therapeutic proteins.

Methods of Cell Culture

- Monolayer Culture:Cells are grown on a flat surface, forming a single layer.

- Suspension Culture:Cells are grown in a liquid medium, allowing them to float freely.

- Microcarrier Culture:Cells are attached to small beads or microcarriers, which provide a larger surface area for cell growth.

Factors Affecting Cell Growth and Viability

Optimal cell growth and viability depend on several factors:

- Culture Medium:Provides essential nutrients, growth factors, and pH buffering.

- Temperature:Most mammalian cells grow optimally at 37°C.

- Gas Exchange:Cells require oxygen and release carbon dioxide; a controlled gas environment is crucial.

- pH:Cells have an optimal pH range, typically between 7.2 and 7.4.

Applications of Cell Culture in Biotechnology

- Drug Screening:Testing the effects of potential drugs on cells in a controlled environment.

- Tissue Engineering:Growing cells on scaffolds to create functional tissues for transplantation.

- Bioproduction:Producing therapeutic proteins and other biomolecules using cultured cells.

- Disease Modeling:Studying the molecular mechanisms of diseases using cultured cells from affected individuals.

Bioreactor Design and Operation: Bio Process Lab Science Olympiad

Bioreactors are vessels designed to provide a controlled environment for the growth and cultivation of cells or microorganisms. The design of a bioreactor is critical to its performance, as it must provide the necessary conditions for cell growth, such as temperature, pH, dissolved oxygen, and nutrient availability.

Types of Bioreactors

There are many different types of bioreactors used in industry, each with its own advantages and disadvantages. The most common types of bioreactors include:

- Stirred-tank bioreactors: These bioreactors are characterized by a stirred tank that provides agitation and mixing of the culture medium. They are commonly used for the cultivation of microorganisms and mammalian cells.

- Airlift bioreactors: These bioreactors use air bubbles to provide agitation and mixing. They are commonly used for the cultivation of microorganisms and plant cells.

- Hollow-fiber bioreactors: These bioreactors use hollow fibers to separate the culture medium from the cells. They are commonly used for the cultivation of mammalian cells.

Factors Affecting Bioreactor Performance

The performance of a bioreactor is affected by a number of factors, including:

- Culture medium: The composition of the culture medium is critical to cell growth. It must provide the necessary nutrients, vitamins, and minerals for cell growth.

- Temperature: The temperature of the culture medium must be controlled within a narrow range to ensure optimal cell growth.

- pH: The pH of the culture medium must also be controlled within a narrow range to ensure optimal cell growth.

- Dissolved oxygen: The dissolved oxygen concentration in the culture medium must be maintained at a level that is sufficient for cell growth.

- Agitation and mixing: The agitation and mixing of the culture medium is necessary to ensure that cells are evenly distributed throughout the bioreactor and that they have access to nutrients and oxygen.

Fermentation Processes

Fermentation is a metabolic process that produces chemical changes in organic substrates through the action of enzymes. In biochemistry, it is narrowly defined as the process in which glucose is broken down anaerobically, meaning in the absence of oxygen. Fermentation is used industrially to produce a wide variety of products, including beverages, food, and pharmaceuticals.There

are two main types of fermentation processes: alcoholic fermentation and lactic acid fermentation. Alcoholic fermentation is used to produce ethanol, which is the alcohol found in beer, wine, and spirits. Lactic acid fermentation is used to produce lactic acid, which is a food additive and preservative.Fermentation

is a versatile process that can be used to produce a wide variety of products. It is a relatively simple and inexpensive process, making it a valuable tool for the biotechnology industry.

Applications of Fermentation in Biotechnology

Fermentation is used in biotechnology to produce a wide variety of products, including:

- Ethanol:Ethanol is used as a fuel, a solvent, and a beverage. It is produced by the alcoholic fermentation of glucose by yeast.

- Lactic acid:Lactic acid is used as a food additive and preservative. It is produced by the lactic acid fermentation of glucose by bacteria.

- Citric acid:Citric acid is used as a food additive and flavoring agent. It is produced by the fermentation of glucose by molds.

- Penicillin:Penicillin is an antibiotic that is used to treat bacterial infections. It is produced by the fermentation of glucose by the mold Penicillium chrysogenum.

- Insulin:Insulin is a hormone that is used to treat diabetes. It is produced by the fermentation of glucose by bacteria.

Downstream Processing

Downstream processing is a critical step in biotechnology that involves the recovery and purification of the desired product from a fermentation broth or other biological source. It is a complex and multi-step process that requires careful optimization to ensure high product yield, purity, and quality.

The principles of downstream processing involve several key steps:

- Cell harvesting: The first step is to separate the cells from the fermentation broth. This can be achieved through various methods such as centrifugation, filtration, or flocculation.

- Cell disruption: The cells are then disrupted to release the intracellular product. This can be done mechanically, chemically, or enzymatically.

- Product recovery: The desired product is then recovered from the cell lysate. This can be achieved through various methods such as precipitation, chromatography, or extraction.

- Product purification: The recovered product is further purified to remove impurities and contaminants. This can be achieved through various methods such as chromatography, crystallization, or ultrafiltration.

Applications of Downstream Processing

Downstream processing has numerous applications in biotechnology, including:

- Production of therapeutic proteins: Downstream processing is used to recover and purify therapeutic proteins, such as antibodies, hormones, and enzymes, from cell culture or fermentation broths.

- Production of biofuels: Downstream processing is used to recover and purify biofuels, such as ethanol and biodiesel, from fermentation broths.

- Production of food additives: Downstream processing is used to recover and purify food additives, such as enzymes, flavors, and colors, from fermentation broths or other biological sources.

Quality Control and Assurance

Quality control and assurance are essential elements of any bio process laboratory. They ensure that the products and processes meet the required standards of quality and safety. Quality control focuses on the testing and monitoring of products and processes to identify and correct any deviations from the established standards.

Quality assurance, on the other hand, is a proactive approach that aims to prevent errors and ensure that the products and processes are consistently of high quality.

Methods for Quality Control and Assurance

There are various methods used for quality control and assurance in a bio process lab. These include:

- Sampling and testing:Samples of raw materials, intermediates, and finished products are collected and tested to ensure that they meet the required specifications.

- Process monitoring:The parameters of the bio process are monitored to ensure that they are within the desired range.

- Validation:The bio process is validated to ensure that it is capable of producing the desired product with the required quality and safety.

- Audits:Audits are conducted to assess the effectiveness of the quality control and assurance system.

Regulatory Requirements for Quality Control and Assurance

The regulatory requirements for quality control and assurance in biotechnology vary depending on the country or region. However, there are some general principles that are common to most regulations. These include:

- The manufacturer must have a quality control and assurance system in place.

- The quality control and assurance system must be documented and maintained.

- The quality control and assurance system must be audited regularly.

The regulatory requirements for quality control and assurance in biotechnology are designed to ensure that the products and processes are safe and effective. By adhering to these requirements, bio process laboratories can help to protect the public health and safety.

FAQ Corner

What are the benefits of participating in the Bio Process Lab Science Olympiad?

Participation in the Bio Process Lab Science Olympiad offers numerous benefits, including the development of critical thinking skills, hands-on experience in biotechnology techniques, and the opportunity to connect with like-minded individuals who share a passion for science.

What are the eligibility criteria for participating in the Bio Process Lab Science Olympiad?

Eligibility criteria may vary depending on the specific competition. Generally, students enrolled in high school or undergraduate programs in science, technology, engineering, or mathematics (STEM) fields are eligible to participate.

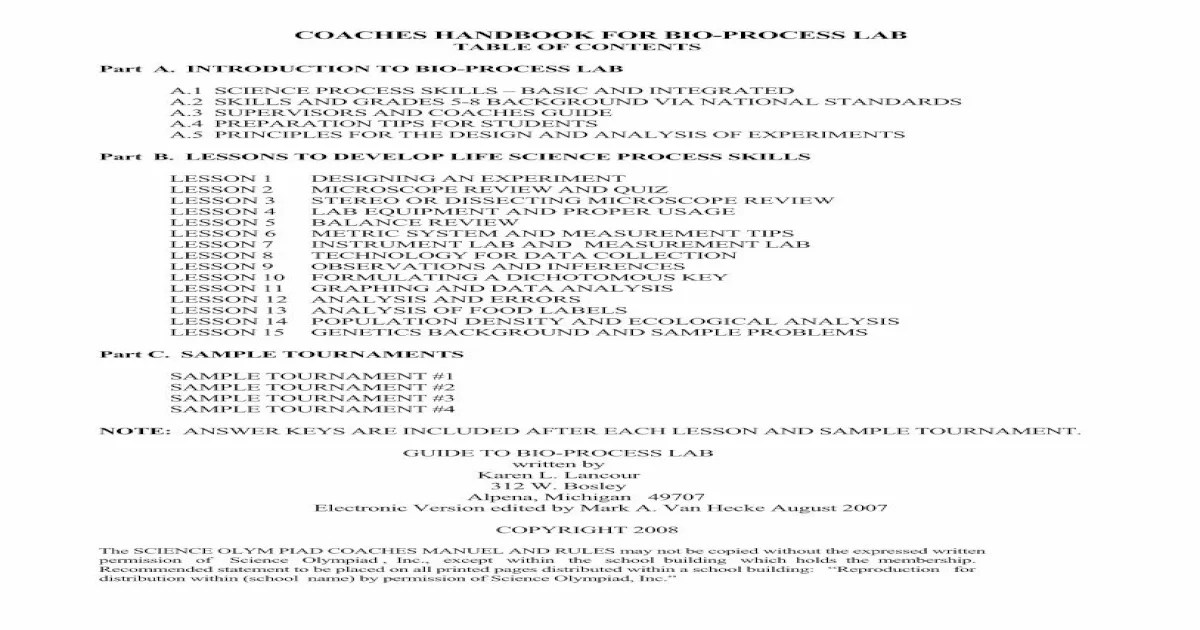

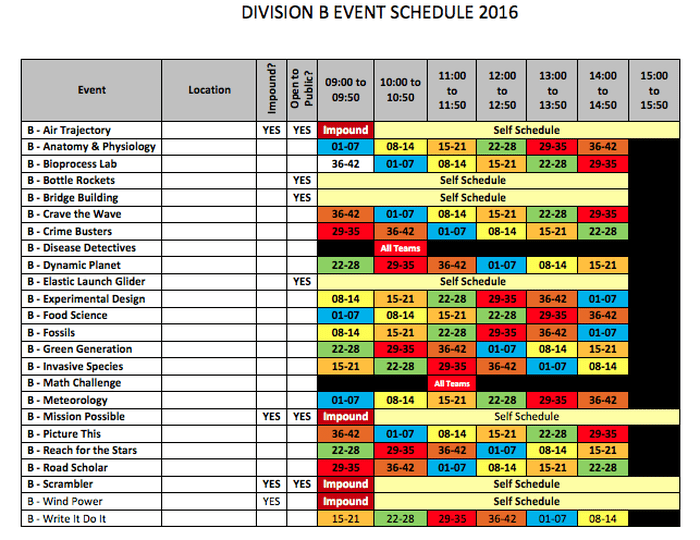

What are the different categories of the Bio Process Lab Science Olympiad?

The Bio Process Lab Science Olympiad typically consists of several categories, such as bioprocess design, cell culture, bioreactor operation, and downstream processing. Each category focuses on a specific aspect of biotechnology and challenges participants to demonstrate their knowledge and skills.